New techniques and technology aim to build resilience – The Vegetable Farmer

While it is quite probably true that vegetable growers currently face more challenges than ever before - they also have more tools, techniques and technology to draw upon than ever...

While it is quite probably true that vegetable growers currently face more challenges than ever before – uncertain weather conditions, climate change, limited options for crop protection, a shortage of labour, depleted soil health and poor economic returns – they also have more tools, techniques and technology to draw upon than ever before writes Richard Crowhurst.

While it is true that growers need to be profitable in order to invest, the range of research projects, start-up companies and new techniques appearing in vegetable production and the wider horticultural sphere suggests that there is no shortage of ideas about how to make our industry more sustainable (in every sense of the word) going forward.

“Given the emphasis on healthy living and moves away from ultra-processed food, it is both frustrating and surprising that vegetable production is still facing so many pressures” comments Belinda Clarke, director of Agri-TechE. “Our grower members – large and small- are facing a ‘triple whammy’ of changeable weather patterns, labour shortages and ever tighter margins. It really just shouldn’t be so challenging for them to provide fresh, nutritious UK-grown vegetables to consumers.”

One area of technology which is becoming commercially operational on UK vegetable farms is robotics. “There is still a lot of hope that automation and robotics will accelerate innovation adoption in the sector – such as the use of robotics in packhouses,” continues Belinda. “Indeed, the previous government pledged financial support to help automate packhouses and to invest in harvesting technologies to make them at least as fast and accurate as human pickers.” ”

I tend to split agricultural robotics into different sorts based on the main types of vehicles,” adds Eliot Dixon, head of robotics and AI at the UK Agri-Tech Centre. “In field veg you have automated tractors, such as the Robotti from Agrointelli and the AgBot from. AgXeed, and there’s a lot of interest in these, with some sales, albeit in limited numbers and some deployment issues around investment costs to overcome.”

He believes that farms growing high value crops with historically high labour requirements will be at the forefront of adopting such machines, particularly where the costs of oversight can be spread over large areas, such as specialist growers and contractors. “The return on investment makes a little more sense because the human oversight is minimal and autonomous,” he explains. “If you need to oversee the machine half the time, the potential benefits are reduced. You may also get some additional benefits in terms of soil health improvement, but most of the current technology is based on quite a large platform and is still relatively heavy compared to tractors from 50 years ago.

“The other sort of robotic technology we are seeing in the veg sector is what I’d call automated, or partially automated, implements such as harvesters. Here we are seeing a lot more uptake, particularly for larger crops, and the Rural Payments Agency (RPA) is starting to funnel funding towards such systems.”

If the commercial uptake of these systems is to increase, Eliot believes a number of things need to happen. “Farmer confidence needs to improve,” he says. “Quite often farmers are portrayed as being scared of risk, but I don’t think that’s true. However, it’s a high-risk industry with very tight margins and things can go very badly wrong very quickly, so growers are understandably risk averse.”

He admits that in the past some technologies have failed to deliver what they promised and believes that the adoption of common standards throughout the industry could help boost confidence in robotics. “There aren’t really any standards that specifically apply to agricultural robotics, so there is an opening for suitable government policy and limited, carefully designed regulation. That would give users confidence that the necessary safety measures have been met and that systems are well designed. We are working with various stakeholders on standardisation and regulation.

“There is also the data side of things. Another reason for the lack of adoption is that some robots are designed for very specific uses, such as harvesting asparagus. They are very good at that, but the implement is integrated into the robot. Changing the implement design and allowing other platforms to use or reintegrate it would improve flexibility. There is no single answer to any farming problem, and you have to be able to adopt relatively open solutions.”

“I think we are getting to the stage where there will be a robot weeder and a robot planter on most decent sized farms,” adds ADAS Consultant Chris Creed. “The driver for growers will be that they’re saving labour, so they can distribute the labour they do have where it is needed, for example for harvest preparation.”

Robotics could also help to increase the value of crops and reduce waste. “While we don’t know if previous government commitments will be honoured, we can expect the new administration to have some thoughts on decarbonisation and the circular economy,” comments Belinda. “Securing higher amounts of marketable crop and reducing waste benefits the entire value chain, and companies like UPP (Upcycled Plant Power) are finding additional revenue streams from by-products – in their case, broccoli trimmings and leaves.”

UPP was co-founded by Pollybell Farms, who wanted to overcome some of the challenges they faced as organic vegetable growers, including a shortage of labour and high levels of waste in crops like broccoli. “Most of the biomass of a broccoli plant is wasted, and because the florets come in a flush over several weeks, you have to walk through the field three or four times and cut the selected heads,” explains UPP CEO Mark Evans. “As a high value but low margin crop, we are losing broccoli production in the UK partly due to losses in the field, but production is also constrained by the availability of casual labour.”

The UPP approach is two-fold. Firstly, it plans on using robotics to overcome the issues around harvesting, while it is also developing a high-protein pulp product from material such as the stems.

“Our harvester concept was proved last year and this year we have a prototype version, with manufacturing planned for next year,” says Mark. “It automatically selects which heads are ripe and ready to be cut, picks them and puts them on the harvester.”

Unlike some other broccoli harvesters which have been developed, the UPP design eschews a robotic arm design for a patented approach using a series of paddles with AI deciding which heads are cut. “The key thing is that we are selectively harvesting,” stresses Mark. “You will find harvesters out there that are slaughter harvesters, picking the lot in one go.” Another advantage is that the UPP harvester is designed to work with existing and conventional broccoli varieties, with recent trials involving Parthenon and Iron Man.

The second part of the UPP business model hopes to exploit the health qualities of broccoli and the fact that much of the stem material is currently wasted. “All the good things that are in the head are in the stalk and the stem as well,” says Mark. “We have a proprietary process to produce a high protein pulp which can be used in products such as burgers up to 20% without any issues. Unlike other sources of vegetable protein, broccoli is hypoallergenic, so you’ve got a protein that is natural and comes from the UK, unlike many soy, pea and wheat proteins which are imported.

“We’ve also developed a high protein fibre product for use in sausages, breads and cakes. And because of how we process you don’t get those sulphur notes of broccoli flavour. Finally, we’re producing a broccoli juice which has about 25g/l of sugar. We’re going to share some of the value of monetising these side streams with growers, so this is a great story for both UK farmers and the planet.”

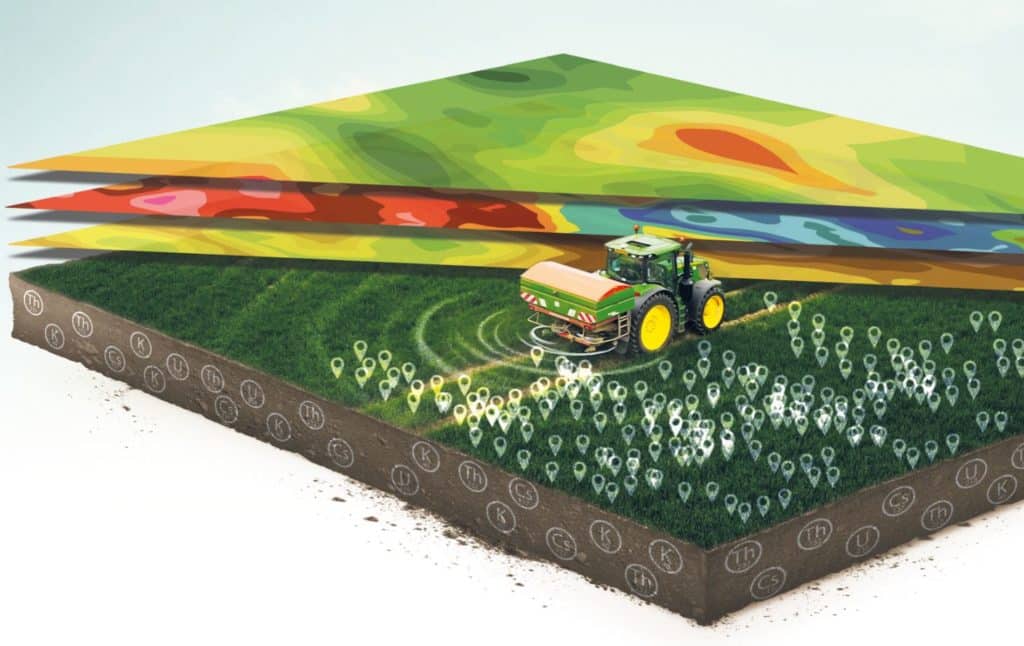

Another technology which has seen a large increase in uptake over recent years is the use of soil mapping and data collection. “Omnia is our farm management software system and TerraMap is our high- definition soil sampling system,” explains Hutchinson’s Nick Strelczuk. “It uses 800 sample points per hectare, compared to some traditional systems that take one per hectare or even one per field. It uses a gamma ray spectrometer fitted to a machine such as an ATV or a pickup. And takes a sample every 10 or 12m, collecting a data point every second. That data is then analysed through the Omnia system, giving us up to 48 different layers of data depending on the package in question.’

Basic analysis includes P, K, Mg and pH, as well as the percentage of sand, silt and clay to determine soil texture. Other packages add soil organic matter, additional information on micronutrients and macronutrients, as well as carbon and active carbon levels. The top-of-the-range Gold service is all about soil health and adds more detail and information on soil activity.

The increased focus on soil health and regenerative farming from the SFI and the supply chain means that Nick and his colleagues have seen more interest in soil data from their grower customers. “A couple of years ago there was a big increase in growers wanting to know their carbon,” he adds.

“There’s been a really big increase in interest in organic matter linked to things like SFI, so our bestselling service at the moment is our standard product plus organic matter info. Then the farms that are interested in regenerative farming, or benchmarking where they’re at now, are also looking at carbon readings, etc.”

While accepting that this generates a lot of data, he believes the way it is integrated into the Omnia system provides a number of benefits. “Omnia is a cloud-based system which you can access anywhere via internet, so it works on Apple, Android, PCs, laptops, etc., stresses Nick. “You can have you multiple users logged in at the same time and can map your farm. Omnia will also allow to create nutrient balances and variable-rate application plans. It’s also compatible with pretty much any sort of machinery out on the market, so there’s a very intuitive import and export feature and you can put files on a memory stick or send them to other cloud-based systems such as John Deere telematics.”

One consideration which is sometimes overlooked by those developing new technologies is that they need to be adaptable and fit in with farming systems. “We’re actually hearing that because of climate change and the increased variability in the weather, some vegetable growers are actually moving away from mechanical weeding back towards using chemical herbicide options where they’re available because this increases the number windows they have to travel on the land,” comments ADAS Horticulture Consultant Ben Barnes.

However, he acknowledges that given the limited number of herbicides available for many veg crops, this isn’t an option for everyone. “Choosing lighter land in general is also a big priority for many growers. Obviously, there’s a limited amount of light land in this country but prioritising that for higher-value vegetable crops to aid better establishment can make the crop more resilient depending on what happens later in the season.”

Crop establishment is another area where automation and robotics are rapidly replacing traditional labour-intensive techniques. “If you’re planting with modules, a traditional module planter needs a team of 12 people,” points out Ben. “However, a technology like PlantTape will work with brassicas, alliums and lettuce and only needs a team of three. You can plant the same number of plants in a day, and while the plants are smaller than modules, so it takes a few more days in the field to grow, many growers are actually finding other advantages such as better rooting, particularly in dry weather. If you are getting better rooting, you can save on irrigation, and its these sorts of pros and cons that need to be assessed so businesses can improve their climate resilience.”